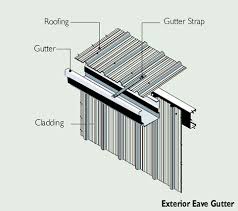

1. EAVE GUTTER AND DOWNSPOUT :

Eave gutters shall be color 0.5MM nominal thickness (26gauge) sheet

Downspouts shall be rectangular shaped, color 0.5mm nominal thickness (26gauge) steel.

Downspouts shall have a 45 degree elbow at the bottom and shall be supported by attachment to the wall covering at 3.0 m maximum spacing.

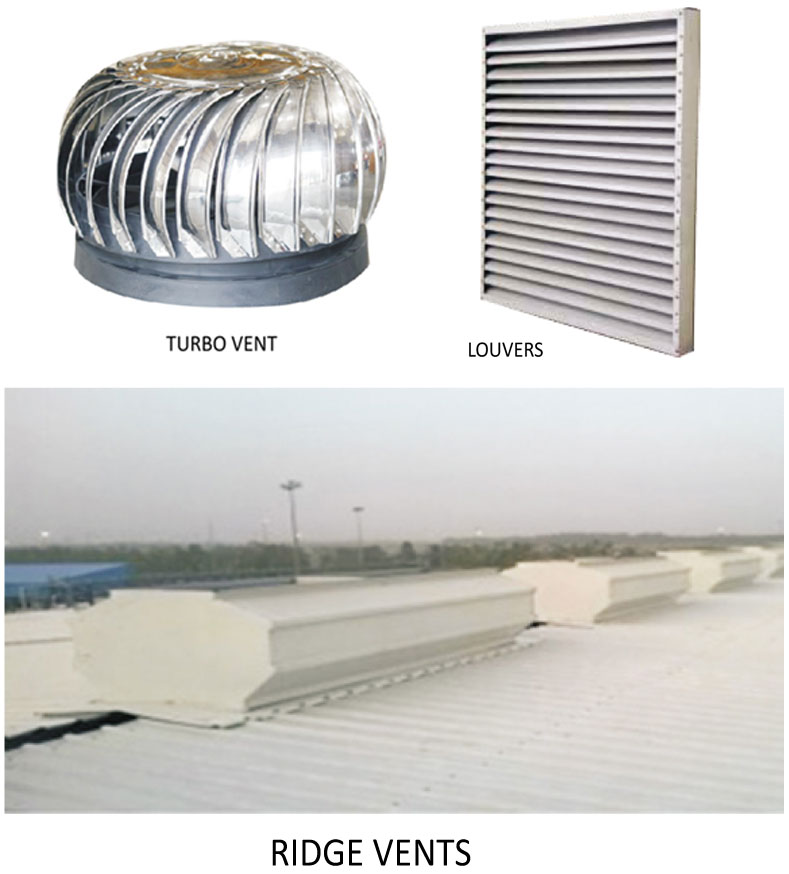

2. VENTILATION:

Ventilation equipments comes in two categories: Inlet Equipment and Outlet Equipment. Either one can be natural or forced. The planning and correct distribution of ventilation equipment has a major role in the overall efficiency of the ventilation system. Ventilation efficiency is also affected by the location of equipment, partitions and doors inside a building.

There are two simple and practical methods for determining ventilation requirements:

1. The Air Change Method, which is based on a recommended rate of air changes per hour for different usages when ventilator capacity is given.

2. The Heat Removal Method, which calculates the volume of air required to remove the heat gain inside a building.

3. Turbo Air Ventilator Turbo Ventilator Extract Hot, Humid and Stale Air by creating a Convection Current which exhausts unwanted air allows Fresh/ Cool Air to replace from outside. This increases workers comfort level, reduces exertion resulting in a higher productivity.

4. A Ridge Vent is a type of vent installed at the peak of a sloped roof which allows warm, humid air to escape a building attic. Ridge vents are most common on shingled residential buildings. Ridge ventilators will control the movement of fresh air through the building removing hot, stale air and air contaminated by manufacturing or production processes. Summer heat is released naturally through gravity ridge ventilators.

5. A wall opening provided with slanted blades, fixed or movable, to allow flow of air inside the building.

3. SKYLIGHT PANELS

Skylights are light transmitting material (elements filling building envelope openings) a portion of, the roof of a buildings space (generally taken as 3% of the roof area) for allowing natural light to enter the building.

Polycarbonate and FRPs are the two types of accessories generally used.

4. INSULATION

Insulation is one of the ideal choices for larger construction sites or building at remote locations where you cannot find much of the installation services easily. Such insulation material when installed correctly, drastically reduce the heat transfer through the roof surface. It useful in all circumstances where there is a bigger temperature difference, higher heat flow or a naturally hot space to a cooler space. It is also useful to maintain a comfort in the winter as it prevent the inside heat to loss in the outer environment. While in summer, it prevents the higher heat that is generated outside entering inside the house. Statistics shows that almost 50% of energy used inside the house is to maintain a specific temperature in hot or cold. And that is why it makes sense to use pre engineering building insulation material to reduce the energy consumption and increasing cost savings.

Pre Engineered building insulation is used in industrial as well as residential constructions. Aluminum material on both of the side and sandwiched single bubble or double bubble polyethylene material happens to be the most favorite combination for reflective insulation. Moreover, there is not heat or thermal absorption involved so there is a very little question about heat transmission and you can go heat insulated for many years.

Insulation is of certain types:

A) Glass Wool Insulation

Glass wool is an insulating material made from fibers of glass arranged using a binder into a texture similar to wool. The process traps many small pockets of air between the glass, and these small air pockets result in high thermal insulation properties.

Glass Wool is widely used for insulation due to its thermal and acoustic insulation properties, tensile strength, light weight and exceptional resilience. Glass wool is an insulating material made from fibers of glass that is arranged using a binder into a texture similar to wool. This process traps many small pockets of air between the glass, and these small air pockets result into the thermal insulation properties that it has with it.

Glass wool is produced in rolls or in slabs, with different thermal and mechanical properties. It may also be produced as a material that can be sprayed or applied in place, on the surface to be insulated. Glass wool is considered to be the most effective and environmentally friendly insulation product to use as it is non-combustible, and meets the requirements for optimal thermal and acoustic insulation performance.

b) Rockwool Insulation

Rockwool, also known as mineral wool or stone wool is a type of insulation made from actual stone. Because it is an excellent insulator, sound baffle and possesses a very high melting point, rockwool is used in a wide array of products and applications.

Rockwool, also known as mineral wool or stone wool is a type of insulation made from actual stone. Because it is an excellent insulator, sound baffle and possesses a very high melting point, rockwool is used in a wide array of products and applications.

The ROCKWOOL TECHNICAL INSULATION products are based on stone wool, which cannot burn and which can stand temperatures up to 1000 degrees C without melting. Thus ROCKWOOL stone wool provides the best guarantee for an effective fire protection on board ships and offshore platforms.

c) Reflective Bubble Insulation

Reflective Bubble Insulation products consist of one or two layers of Barrier Bubble material laminated between layers of metalized film to provide excellent thermal resistance. The bubble contains an air retention layer designed to provide increased strength and puncture resistance.

Insulation is used to either contain heat for maintaining warmth, or to resist heat for maintaining cold. In many applications, radiation is the dominant mode of heat transfer. TempShield® foil bubble is considerably more effective than conventional insulations in reducing radiant heat transfer.

TempShield foil bubble reflects up to 95% of radiant energy in addition to resisting other types of heat transfer thus providing effective insulation.

TempShield is used as insulation against radiant heat transfer and can be used to its greatest advantage in instances where radiation is the predominant means of heat transfer. It is the bright aluminumized film surface of all TempShield products that gives it its insulating properties. This happens in two ways: TempShield is an excellent reflector of all long wave radiant heat that strikes it – reflecting up to 95% of all radiant heat.

TempShield will reradiate only 5% of heat in which it comes in close physical contact, compared with the approximate 90% reradiation of ordinary building materials, at the same temperature.

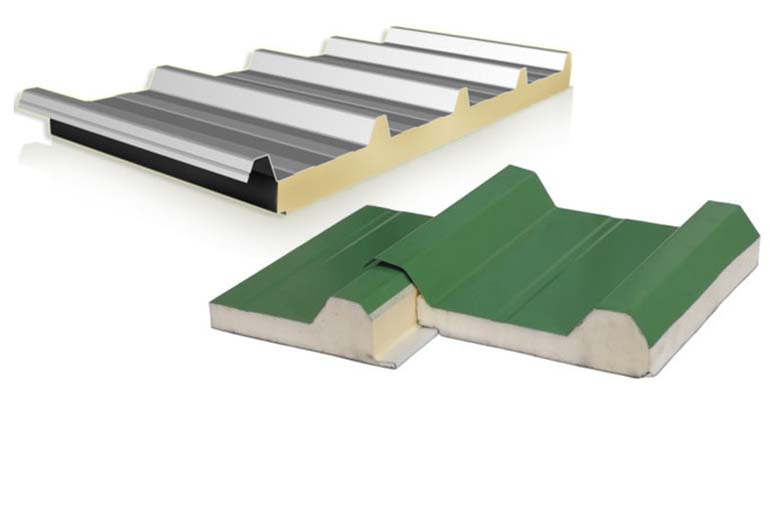

d) Puff Insulation

PUF Insulation materials are suitable for temperature range between -200°C to +110°C. PIR Slabs & Pipe Sections are suitable for use between -200°C to +145°C. It has low thermal conductivity value of maximum 0.021 w/mk at 10°C. It is not easily ignitable and has negligible water permeability. It is suitable for cold / chilled pipelines, building roof & wall insulation, equipment insulation and Horton sphere insulation. Unlike most thermoplastics, PUF / PIR has low smoke emission and will not melt or drip in a fire, Being rigid Polyisocyanurate foam, it also has a higher hot surface performance of 150°C compared with only 110°C of normal Polyurethane Foam. This makes it ideal for use directly over steam or electrical tracing.

With PUF / PIR, insulation thickness can be reduced by 50% compared with cork, 44 compared with expanded polystyrene or fiberglass. It exposes lower surface area, reducing area or expensive vapour barrier and outer cladding per running meter of piping.